Evolution of Metallic Additive Manufacturing (AM) – Part 3

Wire Based Processes in AM

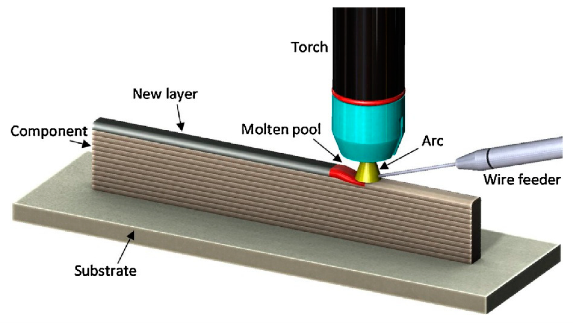

Although Additive Manufacturing initially had its roots in wire-based

processes, it did not develop much beyond the repair and maintenance of large

expensive components like turbine blades, rolling mill rolls, large internal

combustion engines, etc. There is now a renewed interest in these processes to

produce larger components than are available in powder-based technologies. Currently

very few equipment suppliers are engaged in this emerging area.

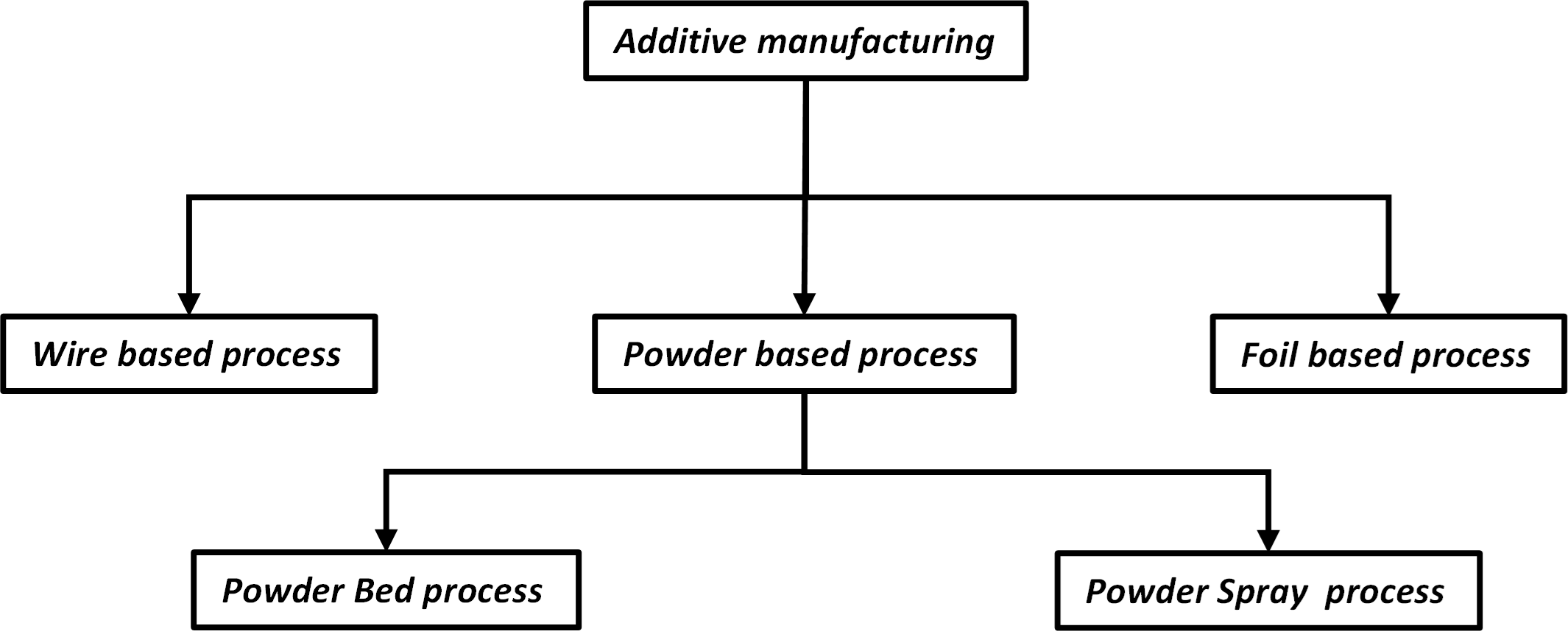

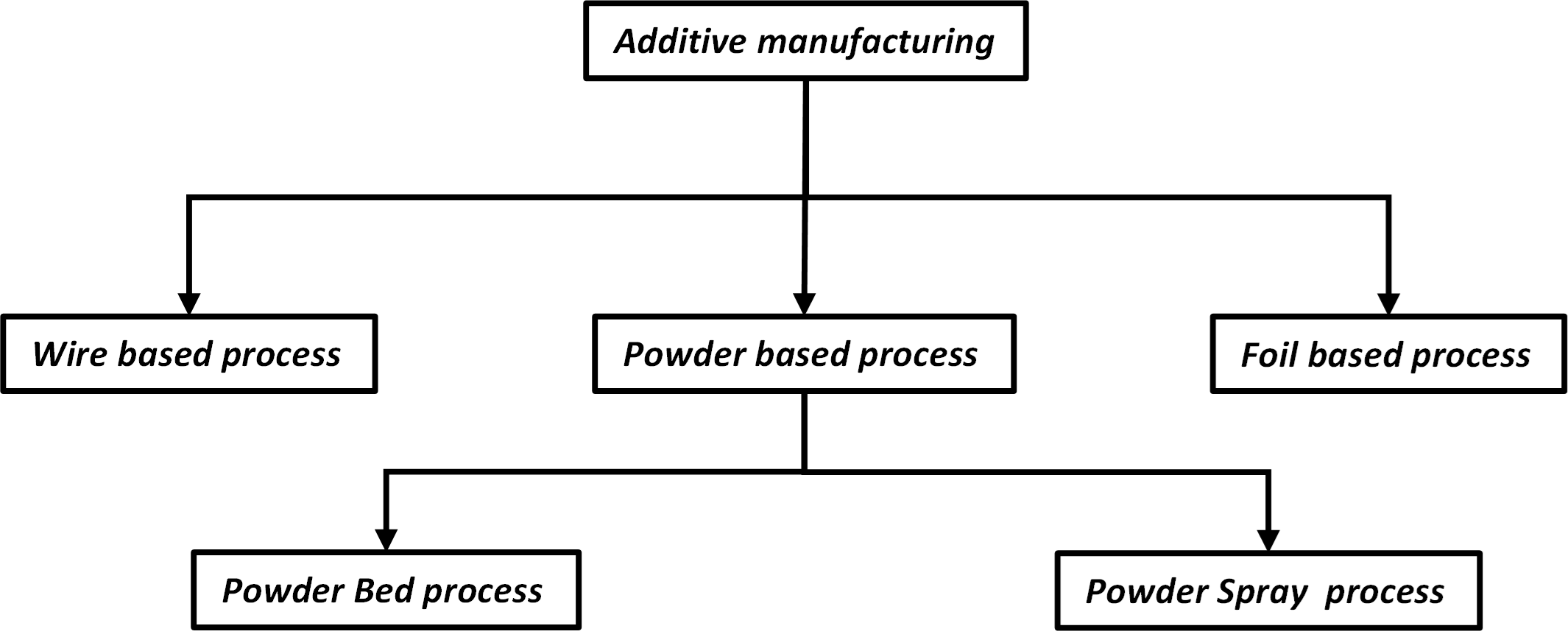

Current Processes for

Metallic Additive Manufacturing

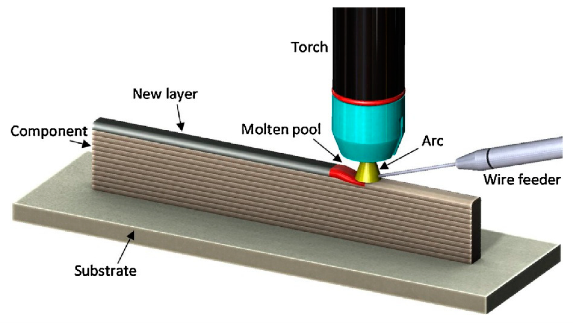

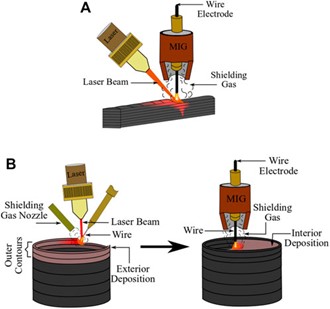

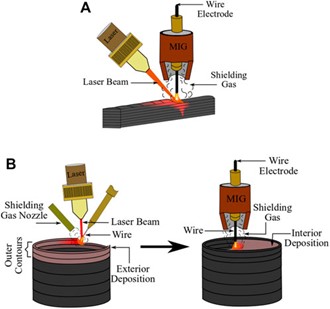

Shown below are some variants of wire-based technologies.

There is a need for metallic feedstock materials that are both suitable for use by the wire arc process and provide higher end-product performance. For example, if one were to produce large aerospace engine or structural components using this process, the availability of suitable feedstock materials is likely to be a concern.

Standard Advanced Products and Services (StandardAPS) is prepared to work closely with product-based customers to develop and supply these new classes of wires for more demanding structural applications. Contact us for your AM feedstock material and product needs.

Have Questions About Additive Manufacturing?

NASA test fires additively manufactured aluminium rocket engine nozzle

NASA has reported the testing of additively manufactured aluminium rocket engine nozzles. Being lig

Ursa Major aims to improve solid rocket motor production with Additive Manufacturing

Ursa Major Technologies Inc has announced an approach to the design and manufacture of solid rocket

Evolution of Metallic Additive Manufacturing (AM) – Part 4

Metallic Additive Manufacturing has moved quickly and deliberately in new manufacturing opportunitie