Evolution of Metallic Additive Manufacturing (AM) – Part 2

Powder Based Processes in AM

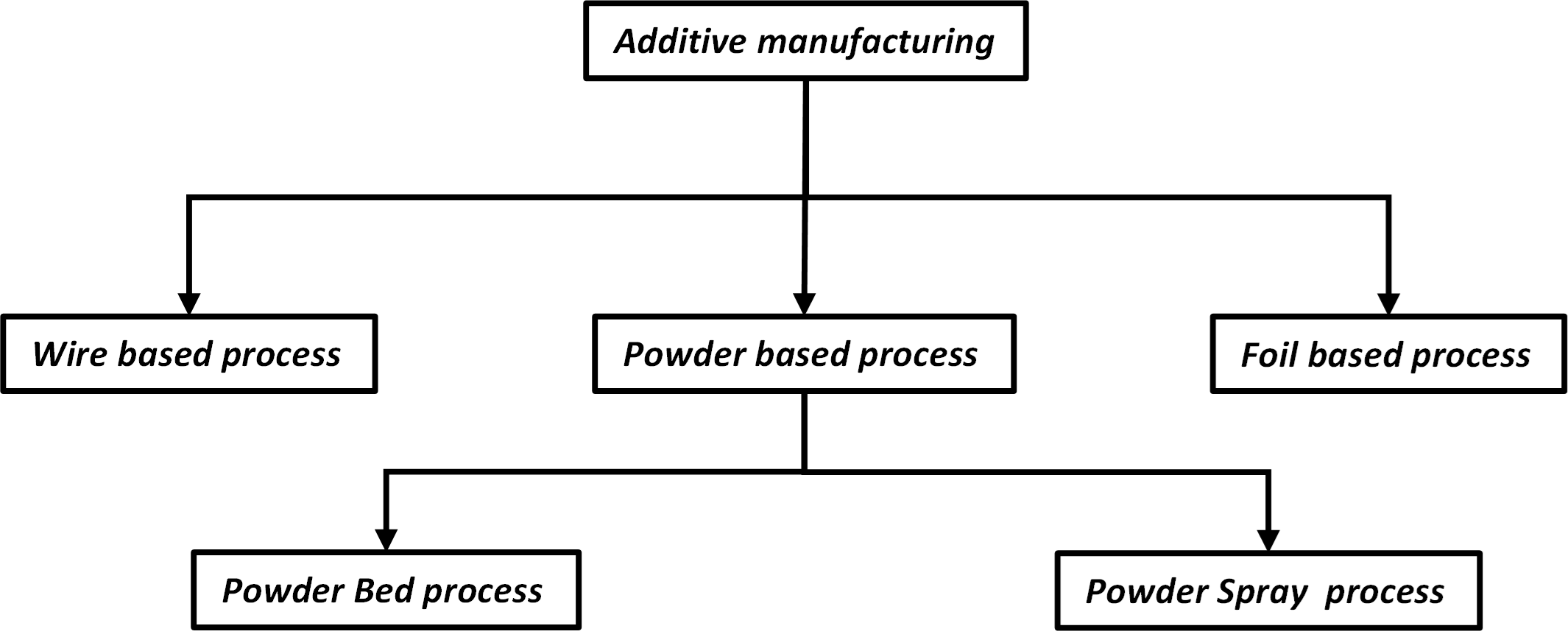

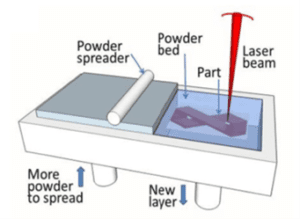

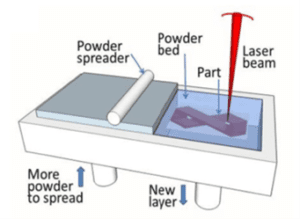

Currently metallic Advanced Manufacturing (AM) is based predominantly on metal alloy powders typically produced by gas or water atomization. Two broad powder based categories of the processes, namely powder bed and powder spray processes, are commercially available today.

Current Processes for

Metallic Additive Manufacturing

Powder bed processing has evolved over a period of decade to become the major process choice today for metallic AM. There are advantages and disadvantages to powder based processes.

A variety of power sources are available today. Most systems are based on laser, while electron beam is used for certain specialized materials, like titanium, niobium, etc. In the case of a laser power source, it can be a traditional gas laser like a CO2 laser, which is guided by articulated mirror mechanism to raster the power source or a solid-state laser like a YAG laser enabled by optical fibers. The power and raster speeds can be adjusted so that only a small quantity of metal is either melted or sintered at any time during the process. Thus, even simple low wattage power sources can be used to build metal components.

Key advantages of this process are the greater availability of systems in the market and it can be tuned to produce large quantities of small components relatively easily at high production rates. One significant disadvantage of powder process is the cost and utilization of feedstock. Due to the need for faster melt rate, the size of the powder particles is restricted to spherical particles less than 45microns in diameter.

The main concern with this requirement is, in typical powder atomization processes, it is difficult to produce powders of less than 45microns consistently. Normally in a typical powder batch this volume generally constitutes only 30-35% of the total powder production in the traditional gas or air or water atomizer. The reminder must be diverted to other applications to reduce the feedstock cost or remelted which still adds cost. In addition, very rarely more than 60% of powders used in the powder bed are utilized in making the components. The rest are generally scrapped adding to the component cost.

This method is useful for some commodity materials that can be processes in air. If the material processing requires a controlled atmosphere, the entire setup must be housed in a controlled atmosphere chamber further adding to the cost. In the case of electron beam-based process, the electron beam generator needs to be housed in vacuum or near vacuum to facilitate the power beam production and use, thus adding further to the initial capital.

The major advantages of the HVOF spray process are it is possible to use a wider distribution of powder particle size and the cost of initial capital is typically lower than laser or electron beam equipment. Advantages of both processes are the ability to build large numbers of small components providing the advantages of scale to reduce component cost as well availability equipment manufacturer to provide system. Still, each process suffers from high raw material costs to a certain extent. If one were to build large components like rocket engine or jet engine components or large aircraft components like landing gears and marine structures, powder-based processes have several size-related limitations. For these larger structural components, either wire or foil-based processes provide significant advantage.

Have Questions About Additive Manufacturing?

NASA test fires additively manufactured aluminium rocket engine nozzle

NASA has reported the testing of additively manufactured aluminium rocket engine nozzles. Being lig

Ursa Major aims to improve solid rocket motor production with Additive Manufacturing

Ursa Major Technologies Inc has announced an approach to the design and manufacture of solid rocket

Evolution of Metallic Additive Manufacturing (AM) – Part 4

Metallic Additive Manufacturing has moved quickly and deliberately in new manufacturing opportunitie